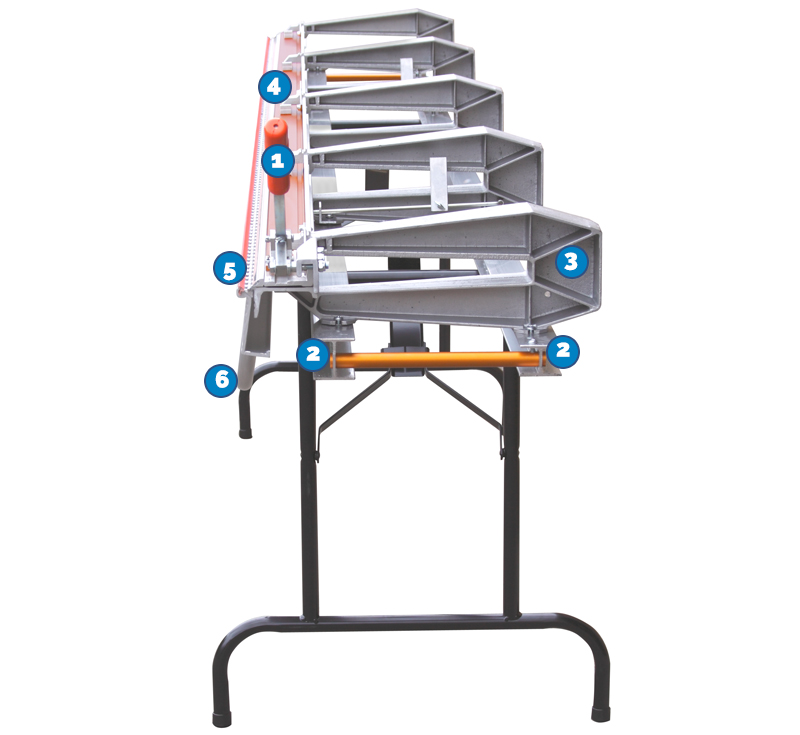

Trim-A-Brake II™

Entry-level Window, Siding, and Trim Bending Brake.

*Model shown with the optional Steel Legs

Features & Benefits

1. Toggle-Lock System

2. Dual Support Base Rails

3. Military Grade Aluminum Castings

The Trim-A-Brake II™ utilizes Military Grade Aluminum Castings to provide a strong and solid clamping pressure.

4. Slide Locking Bar

The reliable, compact slide locking bar on the Trim-A-Brake II™ makes it easy transport and easy to use.

5. Non-marring Vinyl Strip

6. Full Loop Handle

Full loop bending handle connects a 2-4 integrated contact points allowing for straighter, more even bends with one hand operation. Ideal for bending full length (8ft +) pieces.

"I love the trim-A-tables and brakes. Have bought 5 breaks and 2 trim tables over the years. Thanks for the quality products that have helped me thrive throughout the years"

-Myles M.

Newtonville, ON

DETAILS & SPECIFICATIONS

The Trim-A-Brake series was developed in 1964 and remains mostly unchanged thanks to its simple yet proven design. It is an excellent brake that really excels at being affordable and functional for most simple bends that DIY’ers and contractors may need to create. With its incorporated stainless-steel edge, scoring and snapping aluminum coil stock with a utility knife is a breeze. Perfect for 90-degree bends, it can even create 130-degree bends when needed, though highly detailed trim projects may require a more full-featured cam-locking brake.

The TrimCutter was developed in the late 1990’s and was designed to work with our more refined, and newest at the time, cam-locking brakes. These include the Mark I, Mark II TrimMaster, MetalMaster and our Industrial brake models built from 1998 to today. The Trim-A-Brake predates the TrimCutter by almost 30 years, which is why the two products aren’t compatible.

Van Mark brakes are typically sold by themselves, allowing the user to select the ideal accessories to pair with their brake, like stands (we offer multiple leg and stand options), cutters, formers, or a CoilDispenser, allowing for ultimate flexibility in setting up their workflow without buying anything they don’t need or won’t use.

Model Line:

Mark II TrimMaster

Throat Depth:

14"

Hinge Type:

POWERslot™ Click here to learn more

Stand Options:

Sold seperately; Click here for Stands

Warranty:

1 Year

Model Line:

Trim-A-Brake II

Throat Depth:

13 3 ⁄ 8"

Hinge Type:

Traditional Hinge (to hem, please see our TrimMaster® models)

Stand Options:

Sold seperately; Click here for Stands

Warranty:

1 Year

CORE SPECS

Model

Length

Castings

Weight

T200

2'0" (0.61 m)

2 ea.

25 lbs (11.4 kg)

T450

4'6" (1.37 m)

3 ea.

40 lbs (18.2 kg)

T650

6'6" (1.98 m)

4 ea.

58 lbs (26.4 kg)

T850

8'6" (2.59 m)

4 ea.

76 lbs (34.5 kg)

T1050

10'6" (3.20 m)

5 ea.

91 lbs (41.4 kg)

T1250*

12'6" (3.81 m)

7 ea.

112 lbs (50.9 kg)

BENDING CAPACITIES*

Material

Maximum Thickness

Aluminum (3003H14)

.024"

DOCUMENTS & VIDEOS

Documents

Videos

Most fasteners used in Van Mark tools are standard off-the-shelf nuts & bolts. This was intentional. We use standard fasteners to allow you to get back to work more quickly if something goes missing. Using standard replacement hardware like nuts, bolts & pull-pins will not affect your warranty. For more information, please contact Van Mark directly.

For Sales Literature on our Brakes and Accessories, see our Media Package page

WARRANTY

1 Year Manufacturer's Limited Warranty

Van Mark Products Corporation warrants this product against defects in material or workmanship for or a period of 1-year from the date of original purchase. For details, click here.